Advanced Uses of Wire Wound Resistor: Driving Modern Technology

Innovative Applications of Wire Wound Resistors

As electronics evolve rapidly, the these resistive components continue to play a pivotal role in numerous settings. Beyond being a simple resistor, the wire wound resistors place themselves strategically in countless modern devices. Join us as we uncover the multifaceted uses of the wire wound resistors.

High Precision and Control

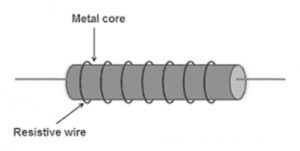

A significant edge that sets wire wound resistors apart is their unprecedented exactness. The precision attained beyond what many counterparts can reach. Their craftsmanship is shown in the winding, enabling stabilized resistance.

In areas needing acute exactness, such as advanced instrumentation creation, these resistors fulfill expected precision. That feature ensures precise recordings aren't compromised even during dynamic operational shifts.

Managing Power Spectra

The capability of the wire wound resistor in managing substantial power loads is responsible for their favored applications. These components can endure without losing operational steadiness.

Innovative energy harnessing solutions like solar energy frameworks and wind-driven generators take advantage of this robust nature. The energy conversion process involves many fluctuating conditions. Wire wound resistors become invaluable assets here, stabilizing electrical signals to ensure optimal conversion efficiency.

Modern Developments in Resistor Applications

The pathway gadgets are taking steers how resistors are made. At present, wire wound resistors are combining into connected ecosystems as part of the Internet of Things (IoT).

Intelligent electrical networks are a key frontier. These essentially powered grids owe much to wire wound resistors. Wire wound resistors in circuits ensure point-specific control across mass-scale frameworks, achieving electrical harmony. Their inclusion helps streamline and support green technology goals.

Selecting Wire Wound Resistors

When deciding on a wire wound resistor demands comprehension of intended functions. Resistance rating, power capability, and environmental conditions must be weighed carefully. Assessing these factors offers straightforward guidance in making the most suitable choice.

Being diligent in this process secures correct resistor application. Besides this, consultation with manufacturers enhances decision-making, tailoring specific resistor solutions that conform to environment-centered tasks.

Future Directions

In alignment with electronic advances, these resistive components require innovative growth. The wave of making things smaller might challenge the current designs, calling for thinner versions that don't sacrifice power. New findings in material capabilities are likely to unveil novel construction offering enhanced performance.

Concurrent with these materials advancements, working alongside software systems could allow dynamic resistor adjustments, injecting digital intelligence in resistors. The integration will cause resonance between resistors and smart infrastructures, enhancing operational efficiencies. Pioneering developers propel these forward journeys, ensuring that wire wound resistors flourish for years to come.